DECAN

- Depallettizzatore DECAN

- Depallettizzatore DECAN

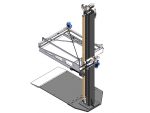

The DECAN model is a stationary vane depalletizer, equipped with a structure made of painted steel and a support base in AISI 304 stainless steel.

The pallet of cans is not lifted and the distribution of the cans takes place without any twist movement, which also involves a considerable waste of water during rinsing: the cans are picked up by a mechanical arm by means of a suction system and they are then released at the level of the conveyor belt (1 or 2 rows at a time). This therefore avoids the operator having to work at height (the equipment does not require stairs and walkways) and allows a quick and convenient can format change.

This depalletizer is extremely versatile and can be adapted to various pallet sizes by positioning appropriate regulators; its small footprint also allows installation even in confined spaces and the absence of side barriers allows a much easier loading of the pallet on the load base: this is equipped with a loading ramp specially designed to prevent the pallet from overturning during positioning on the base itself by the operator.

This depalletizer can be combined with the CAN JET unit, a high-speed (max. 4000 bph) can rinsing machine that can also mark the production batch and / or the expiry date on the bottom of the can in the same cycle, a marking that is actually carried out on a dry surface and at room temperature ensuring maximum durability over time.

Controlled three-phase motorization.

Equipment with CE-compliant safety devices.